The utility model relates to an anti pollution air valve, which is a new type of air valve designed for the bad working environment, and can satisfy the high efficiency and reliability under the extreme working conditions. For example: 1, coal chemical industry in the field of water gas, coal bed gas, petrochemical industry, such as exhaust gas contains a large number of dust, tar or other pollutants. Lead to valve blockage and other consequences due to viscous effects. 2, in many chemical devices, polymer into the compressor caused by the valve plug and other due to viscous effects. 3, as a result of excessive oil and condensate into the valve, resulting in liquid hit.

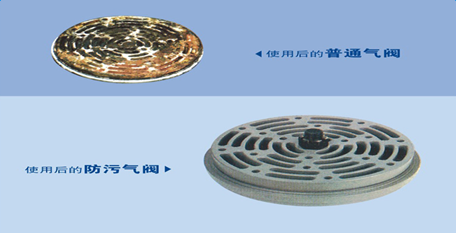

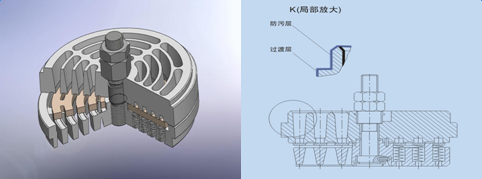

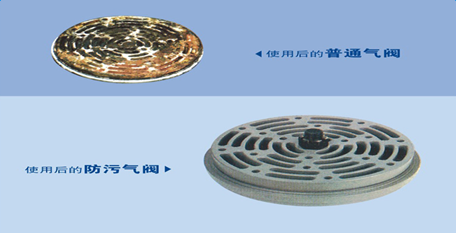

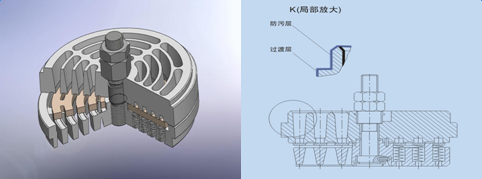

The antifouling valve comprises a valve seat, valve cover, valve bolt, nut and spring, the body is provided with a gas tank, which is added to the transition layer and the antifouling layer on the surface of the valve seat and a valve cover on the valve cover and spring, and will make appropriate technical improvements, making the valve components in complex gas working condition. The airflow channel is not sticky dirt blocking, valve seat and the valve cover adhesion is greatly reduced and the movement path of the valve to return to normal, thus greatly improve the service life of valves, good energy-saving effect 5-10%.

The design features of anti fouling compressor: 1, wide channel, wide sealing surface ---- air tightness, flow characteristics, energy saving, 2, corrosion resistance, high temperature resistance, high lift, 3 - flow area, valve loss is small, the impact of PEEK valve 4, high performance, valve seat, valve wear small, low noise, 5, special valve structure design - reducing valve tilting motion, 6, thick spring ---- low stress, long service life, 7, anti - pollution treatment liquid hammer, anti oil, anti impurity, viscosity is not easy to accumulate, good reliability, anti - Design Optimization of 8, valve cover oil viscosity after these, the intake valve plug cleaning cycle greatly extended, valve efficiency and long operation cycle greatly improved, to ensure the safe and stable operation of equipment and system, reach the purpose of high efficiency and saving energy.

The antifouling valve application has solved many practical problems, eased due to valve blockage caused by compressor need frequent cleaning and replacement of valve parking problems, reduce the work intensity of maintenance workers, improve the work efficiency to improve the operation reliability of the compressor.